Hi, I’m Rich Lesnik.

I have a BA in US History from the University of Pennsylvania (College ’68), have worked as a cab driver, short-order cook, substitute teacher, left-wing political activist, librarian, recording engineer, jazz musician (alto saxophone, clarinet and flute), typesetter, aircraft mechanic, and now, a bicycle wheelbuilder. I’ll be posting more information about my “other” life as time goes by, elsewhere on the website.

From THEN to NOW

When I took an early retirement from the airline in 2002, I needed a part-time job, so I figured I might as well look in the bicycle industry for work. My favorite outfit is Rivendell Bicycle Works — I’ve been an ardent fan and Rivendell member for years — so I applied for a job. Didn’t start with wheels, though. I did pretty much everything else, other than mechanic work! Then, when Rivendell’s main wheel supplier went out of business, I established Hands on Wheels, and made a bid for the work. Thus started a long relationship of trust and mutual respect. Hands on Wheels and Rivendell are developing a reputation as as THE place to come for the best wheels around.

My method

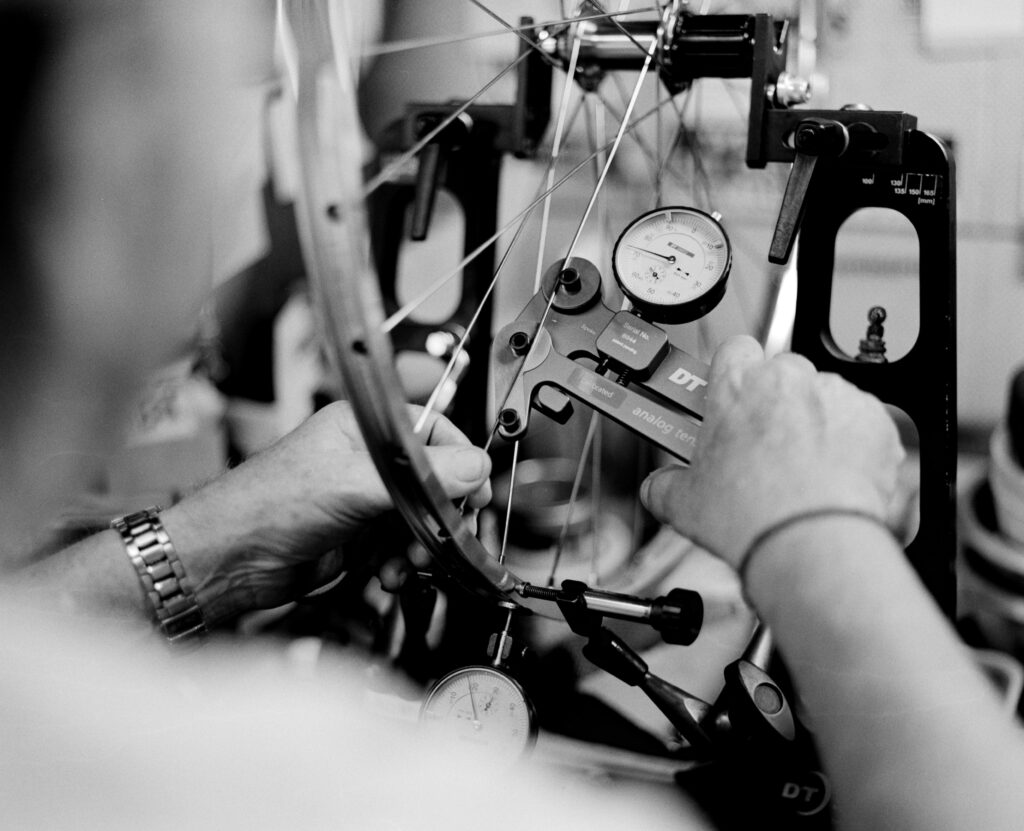

All of my wheels are built completely by hand — starting with hub, rim, DTSwiss or Sapim double-butted stainless steel spokes and nickle-plated brass nipples. Each wheel is laced to no-tension, then transferred to the DTSwiss wheelbuilding stand for finishing and fine-tuning. Many factors — an uncooperative rim, finicky eyelet or spoke-hole, occasional irregularity on a machined braking surface — give each wheel it’s own “personality”. I make no claims about speed or “ease” when it comes to building a wheel. Every wheel approaches its finish in its own time, and I allow whatever time it takes to let that happen.

My guarantee

When I put the finishing touches on each wheel, I guarantee that wheel to be round and true, with no broken spokes, for the life of the rim. Any claims against that guarantee will be corrected, or paid for, by me, at no charge. I may ask to “split” shipping costs if there’s a big expense there — but I’ll pay for the customer to have the wheel repaired locally if that’s a problem.